In the vast expanse of a warehouse, lighting plays a pivotal role that often goes unnoticed. At first glance, it might seem like a mere functional requirement, but delve a little deeper, and you’ll find that the right lighting can be the difference between a productive workspace and one riddled with inefficiencies and potential hazards.

Warehouse lights are not just about illuminating spaces; it’s about creating an environment where workers can perform their tasks with ease and precision. Imagine trying to locate a specific item in a dimly lit aisle or attempting to read labels and barcodes under poor lighting conditions. Such scenarios not only hamper productivity but can also lead to errors that might cost businesses in the long run.

Safety, another paramount concern in warehouses, is directly influenced by lighting. Properly lit areas reduce the risk of accidents, such as trips, falls, or collisions with machinery. In a setting where heavy equipment and fast-paced movement are the norms, visibility becomes a critical factor. A well-lit warehouse ensures that workers can see and be seen, making their movements predictable and reducing the chances of mishaps.

Furthermore, the psychological impact of lighting shouldn’t be underestimated. A bright and well-lit environment can boost worker morale, reduce fatigue, and enhance overall well-being. On the contrary, poor lighting can lead to eye strain, headaches, and a general sense of discomfort, all of which can affect a worker’s performance and health.

In the age of sustainability, the type of lighting used in warehouses also has environmental implications. Modern solutions, like LED lights, not only provide better illumination but are also energy-efficient, reducing the carbon footprint of warehouses.

Table of Contents

The Evolution of Warehouse Lighting: Traces the history and transition from traditional to LED lighting.

The journey of warehouse lighting is a fascinating tale of technological advancements and changing priorities. In the early days, warehouses relied heavily on natural light, with large windows and skylights being the primary sources of illumination. However, as warehouses grew in size and operations extended beyond daylight hours, the need for artificial lighting became evident.

Enter the era of incandescent bulbs. Invented by Thomas Edison in the late 19th century, these bulbs became the standard for warehouse lighting for several decades. They provided a warm glow and were relatively inexpensive. However, their energy inefficiency and short lifespan soon became apparent, especially in large-scale operations where lighting played a crucial role.

The quest for better lighting solutions led to the adoption of fluorescent lights in the mid-20th century. These tubes, filled with a bit of mercury vapor, emitted a cooler and brighter light than their incandescent counterparts and were more energy-efficient. For a time, they were the go-to choice for many warehouses.

However, the true revolution in warehouse lighting came with the advent of LED (Light Emitting Diode) technology. LEDs offered a plethora of advantages over traditional lighting solutions. They consumed significantly less power, had a longer lifespan, and provided consistent and bright illumination. Moreover, LEDs could be easily integrated with smart systems, allowing for better control and adaptability

A historical perspective on lighting in warehouses

The story of warehouse lighting is a testament to human ingenuity and the relentless pursuit of efficiency. In the early days, warehouses were primarily illuminated by the sun’s rays. Large windows and strategically placed skylights ensured that the interiors received ample natural light. This reliance on daylight was both economical and practical, but it had its limitations. As commerce grew and warehouses expanded in size, relying solely on the sun became increasingly impractical.

By the late 19th and early 20th centuries, as electricity became more accessible, artificial lighting began making its way into warehouses. The incandescent bulb, a marvel of its time, became a staple. Its warm glow filled warehouses, allowing operations to continue beyond daylight hours. However, while these bulbs were revolutionary, they were not particularly energy-efficient and had a relatively short lifespan.

As the 20th century progressed, the quest for better, more efficient lighting solutions led to the rise of fluorescent lights. These tubes emitted a brighter, cooler light and were more energy-efficient than incandescents. They quickly became the preferred choice for many large-scale operations, marking a significant shift in warehouse lighting practices.

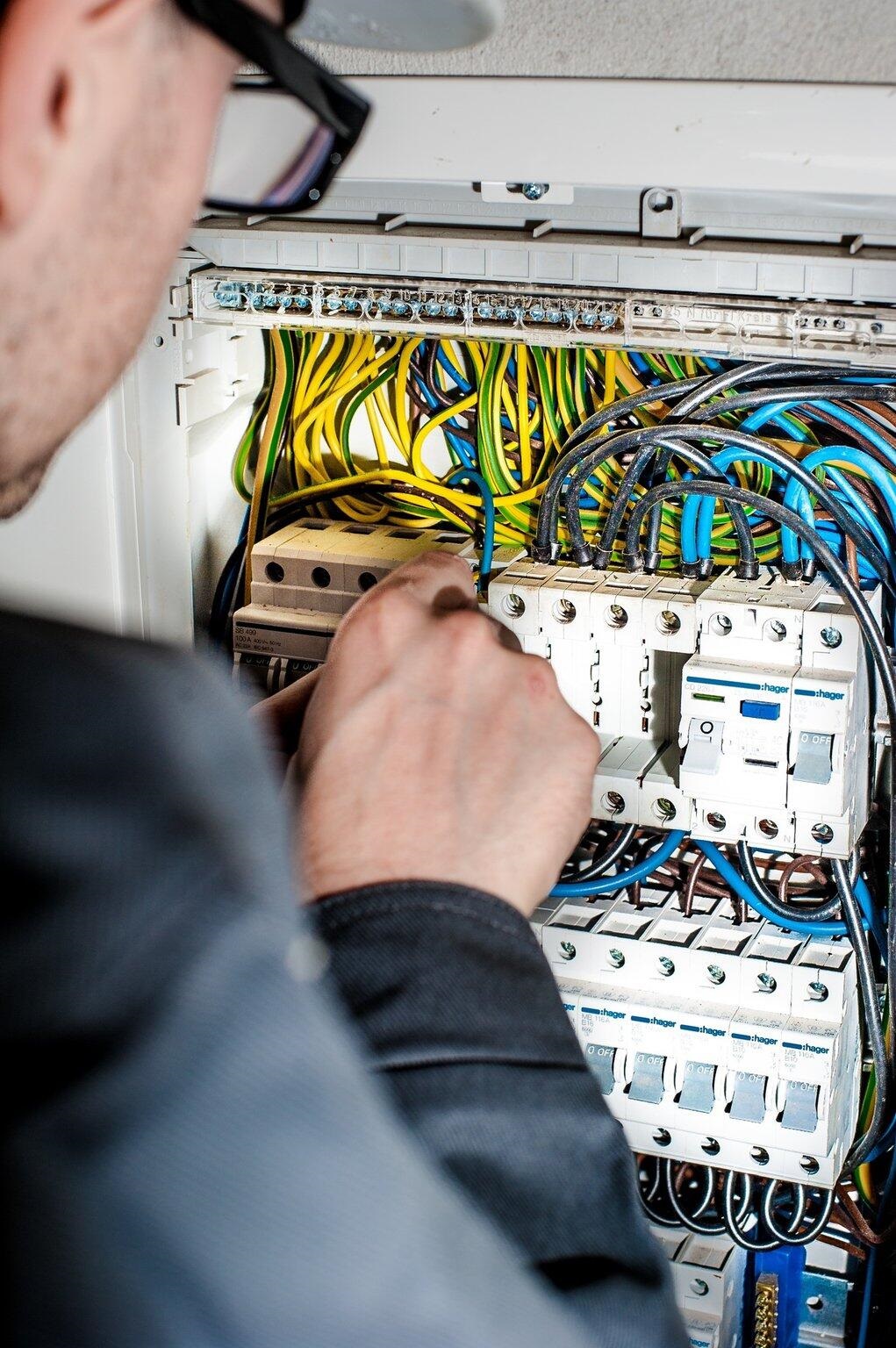

Types of Warehouse Lighting

Warehouse lighting is crucial for ensuring safety, improving productivity, and reducing energy costs. The right type of lighting can make a significant difference in the overall efficiency and effectiveness of warehouse operations. Here are the main types of warehouse lighting:

High Bay Lighting: Used for high ceiling applications.

High Bay Lighting is specifically designed for spaces with ceiling heights exceeding 20 feet. In vast warehouses, where the vertical space is expansive, ensuring even and adequate illumination becomes a challenge. High Bay lights, often characterized by their powerful brightness and wide dispersion, effectively address this challenge. They are typically hung from the ceiling via hooks, chains, or pendants and use LED, metal halide, or high-intensity discharge bulbs. The advantage of using High Bay Lighting in such settings is the prevention of shadows and dark spots, ensuring a uniformly lit environment conducive to safe and efficient operations.

Low Bay Lighting: Used for lower ceiling areas

For areas with ceiling heights typically between 12 to 20 feet, Low Bay Lighting is the preferred choice. These lights are similar in design to their high bay counterparts but are adapted for closer proximity to the ground. They provide a more concentrated light, ensuring that the illumination is neither too harsh nor too dim for the given space. Commonly found in packing or assembly areas within warehouses, Low Bay lights ensure that workers have the right amount of light to carry out their tasks without experiencing eye strain or glare.

Task Lighting: Specific lighting for workstations or particular tasks

Task Lighting zeroes in on specific areas or workstations, providing focused illumination for detailed tasks. Whether it’s reading labels, assembling parts, or inspecting goods, task lighting ensures that workers have the precise amount of light they need. This type of lighting is essential in areas where precision and attention to detail are paramount. By providing targeted illumination, task lights reduce the risk of errors, enhance productivity, and ensure the well-being of workers by reducing eye strain.

Ambient Lighting: Overall lighting for the warehouse

Ambient Lighting is the primary source of illumination in a warehouse, setting the overall light level in a space. It provides a consistent, general light that fills the entirety of the warehouse, ensuring that there are no drastic contrasts or dark spots. While task lighting focuses on specific areas, ambient lighting ensures that the broader environment is well-lit, creating a comfortable and safe working atmosphere. It acts as a foundational layer of light, upon which other lighting types, like task or emergency lights, can be added.

Emergency Lighting: Essential for safety during power outages

Safety is paramount in any workspace, and warehouses are no exception. Emergency Lighting plays a critical role in ensuring that, in the event of a power outage or other emergencies, workers can safely navigate their way out of the building. These lights are battery-backed, automatically turning on when the primary power source is interrupted. Beyond just exit paths, emergency lighting also illuminates critical equipment or areas, ensuring that workers can safely shut down machinery or secure hazardous materials. In essence, while they might not be used daily, their importance in crisis scenarios cannot be overstated.

Benefits of Proper Warehouse Lighting

Proper warehouse lighting offers a multitude of benefits that can impact safety, productivity, and operational costs. Here are some of the primary benefits:

Enhancing Worker Productivity: How Lighting Affects Work Efficiency.

The correlation between proper lighting and worker productivity is undeniable. A well-lit environment not only makes it easier for employees to see and perform their tasks but also significantly impacts their mood and energy levels. When workers can clearly see labels, read instructions, and identify objects without straining their eyes, they can work faster and make fewer errors. Moreover, adequate lighting reduces fatigue and the potential for headaches, ensuring that employees remain alert and focused throughout their shifts. In essence, the right lighting creates an environment where workers can operate at their best, leading to increased efficiency and higher output.

Safety Concerns: Reducing accidents and mishaps.

Safety is paramount in any industrial setting, and warehouses are no exception. Proper lighting plays a crucial role in minimizing risks and ensuring a safe working environment. Dark spots or uneven lighting can lead to accidents, such as trips, falls, or collisions with machinery. By ensuring that every corner of the warehouse is adequately lit, workers can move confidently, knowing that they can see and be seen by their colleagues. Moreover, well-lit spaces make it easier to spot potential hazards, like spilled liquids or obstructed pathways, allowing for timely interventions and reducing the chances of mishaps.

Energy Efficiency: LED lights vs. traditional lighting solutions.

The shift to LED lighting in warehouses is not just a nod to modern technology but also a commitment to energy efficiency. Traditional lighting solutions, like incandescent or fluorescent bulbs, consume more power and often provide less optimal illumination. In contrast, LED lights deliver bright, consistent lighting while using a fraction of the energy. Over time, this translates to significant savings in electricity bills. Moreover, the reduced energy consumption of LEDs means a smaller carbon footprint, making them an environmentally friendly choice for warehouses aiming for sustainable operations.

Longevity and Maintenance: Reduced need for frequent replacements.

One of the often-overlooked benefits of proper warehouse lighting is the reduced need for maintenance and replacements. High-quality lighting solutions, especially LEDs, are designed to last. They offer longer lifespans compared to traditional bulbs, meaning fewer disruptions due to maintenance or replacements. This longevity not only reduces costs but also ensures that warehouse operations remain uninterrupted. Furthermore, modern lighting systems often come with features that alert facility managers to potential issues, allowing for proactive maintenance and reducing the chances of sudden outages.

Related Post: Enjoy the Balinese Way of Living Going Back to Nature