Modern software solutions have undeniably changed the way businesses operate. However, the true value lies in utilizing the appropriate options for specific industries. One place where the right solution can have tremendous advantages is in the industrial realm. By utilizing specialist programs to help engineers and researchers come to the sorts of conclusions that make an impact, businesses in these kinds of industries can increase their bottom line through increases in efficiency and waste reduction. This post will explore what it means to invest in the right solutions and how they can dramatically boost operational efficiency.

Table of Contents

Increased Efficiency And Productivity Levels

Industrial types of businesses are always looking for ways to boost their efficiency levels in order to stay competitive and reduce costs. The right software can help to streamline options and automate manual tasks. For instance, when businesses opt for a chemical process simulation with VisiMix, they can massively cut down their research time and bring a product to market safely in the knowledge that it will work as intended. This kind of productivity can yield enormous gains regarding profit and can particularly help smaller operations to compete with larger ones without the need to invest in large engineering departments.

Enhanced Data Accuracy And Analysis

Along with increased efficiency, software solutions enable industrial businesses to take advantage of enhanced data accuracy and analysis capabilities that can drive meaningful improvements. Companies are gaining unprecedented insights into production processes by collecting operational data from machinery, sensors, and other devices. Powerful analytics and visualization allow firms to analyze key performance indicators more carefully, detect inefficiencies, and, most pertinently, pinpoint areas for optimization and generate meaningful results. Rather than relying on sporadic machine logs and manual data cruising, which is time-consuming and error-prone, those who leverage software for data management and analytics find actionable intelligence to make evidence-based and continuous improvements.

Cost Savings And Optimization Strategies

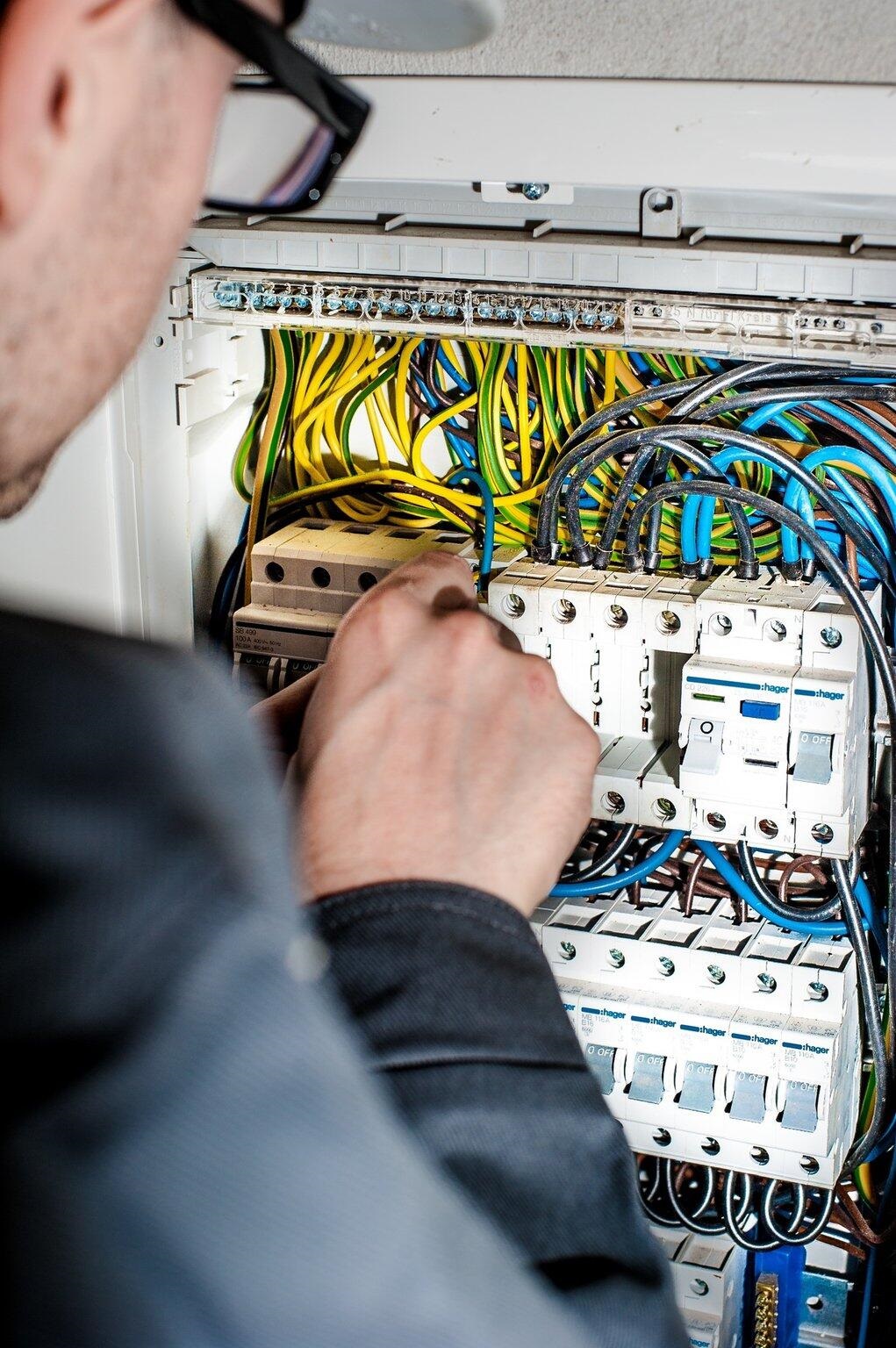

With visibility into real-time production metrics and key performance indicators across all assets and work processes, inefficiencies can be readily identified. Detailed analytics uncover where excess and unnecessary material, labor, or energy consumption occurs to pinpoint cost-cutting areas. Predictive maintenance signals from sensor data prevent costly downtime by alerting to potential issues before failure occurs. Personnel have means to carefully simulate different “what-if” scenarios to find optimal machine settings and workflow configurations that maximize output while minimizing variable expenses.

Reduced Risk Of Human Error

Sophisticated software solutions are aiding industrial businesses in significantly reducing the risk of human error impacting their operations. Advanced systems powered by sensors, automation controllers, and analytics can take over dangerous or repetitive tasks that previously relied on manual labor, lessening the chances of accidents or mistakes occurring. Personnel are freed from tedious data collection duties and given tools to remotely monitor processes from a single control room, helping ensure protocols are followed and issues addressed promptly before escalating. Predictive maintenance notifications spare technicians from unplanned downtime events through timely repairs or parts replacements. With these digital aids, industrial companies lower safety incidents while also decreasing unnecessary reworks and waste due to human fallibility. Their operations become more consistent and reliable with technology augmenting human performance.

Although the word “software” is a bit of a catch-all term for a range of solutions, those aimed squarley at industrial businesses can help them to reduce human error and increase performance-based results. Businesses can dramatically boost profits and reduce waste by utilizing the right programs.