Efficient warehouse storage saves time, space, and money. Poor organization causes delays and increases costs. Warehouse pallet storage solutions help use space better and protect inventory.

Proper storage keeps operations safe and organized. Choosing the right methods improves workflow for workers and equipment. Start exploring strategies now to make your warehouse more efficient.

Read the sections below to learn practical ways to optimize pallet storage.

Maximizing Vertical Space

Using tall shelving allows more pallets in the same area. Vertical storage frees up floor space for movement and other equipment. Racks should match pallet size and weight limits. Proper labeling ensures easy access and tracking.

Safety barriers prevent accidents from falling items. Regular inspections keep racks stable and safe. Forklifts must have enough clearance to reach the top levels. Maximize space without compromising safety. Efficient vertical use reduces clutter.

Choosing the Right Pallet Racks

Different pallet racks suit different warehouse needs. Select racks based on pallet weight and inventory turnover. Standard racks are simple and cost-effective. Drive-in racks hold more pallets in deep storage areas.

Ensure racks are installed securely and follow safety codes. Proper spacing prevents forklift damage. Labels and markers help workers locate items quickly. Racks should allow for ventilation if storing sensitive items. Choosing the right racks increases efficiency.

Optimizing Floor Layout

Organize aisles to minimize travel distance. Keep frequently used pallets near shipping areas. Wide aisles improve safety for workers and equipment. Place heavier pallets at lower levels. Plan for future expansion and adjustments.

Clear signage reduces confusion. Group similar items together for faster access. Avoid dead-end spaces that waste room. A well-planned layout improves productivity.

Implementing FIFO and LIFO Systems

FIFO (first in, first out) ensures older stock is used first. LIFO (last in, first out) can work for non-perishable items. Proper systems prevent product loss and expiration. Label pallets clearly with dates.

Train staff to follow the chosen system. Use racks designed for these methods. Regular audits keep the system accurate. Systems reduce waste and improve rotation. Effective stock management saves costs.

Using Mobile Storage Units

Mobile racks can move on tracks to open aisles only when needed. This increases storage density. It works well in warehouses with limited space. Safety locks prevent movement during loading.

Mobile units should be maintained regularly. Use them for seasonal or bulk items. They save floor space and improve access. Consider mobility options for flexible layouts. Mobile storage adapts to changing needs.

Safety Considerations

Always follow weight limits for racks and pallets. Ensure forklifts are trained and certified. Install safety barriers around high-traffic areas. Keep fire exits and aisles clear. Regularly inspect equipment for damage.

Use proper signage for hazards. Store hazardous materials separately and implement emergency plans for accidents. Safety reduces losses and protects employees.

Proper Pallet Selection

Use pallets that match your storage needs. Wooden pallets are common and sturdy. Plastic pallets resist moisture and pests. Metal pallets support heavier loads. Avoid damaged pallets to prevent accidents.

Standardize pallet size for consistent stacking. Inspect pallets before use. Replace worn pallets promptly. Proper selection improves efficiency and safety.

Efficient Inventory Tracking

Track all pallets entering and leaving storage. Use simple logs or digital systems. Label pallets with barcodes for faster scanning. Update records in real time. Regular audits prevent stock discrepancies.

Track movement patterns to optimize layout. Ensure staff follow tracking protocols. Accurate tracking reduces lost items. Inventory control improves workflow.

Easy Access Design

Place frequently used items at eye level or lower. Use clearly marked aisles and racks. Avoid stacking pallets too high. Ensure forklifts can reach all areas easily. Organize by category for faster picking.

Implement picking lists or maps for workers. Remove obstacles that slow access. Easy access saves time and reduces errors. Workers can operate more efficiently.

Climate and Environment Control

Store items in suitable temperature and humidity conditions. Sensitive products need climate control. Avoid direct sunlight or damp areas. Proper ventilation prevents mold and damage.

Use fans or dehumidifiers if needed. Monitor conditions regularly. Arrange pallets to allow air circulation. Adapt storage solutions for seasonal changes. Controlled environments protect inventory.

Flexible Storage Options

Adjust racks and shelving as needs change. Use modular units for easy reconfiguration. Combine different types of storage for varied items. Temporary storage solutions help during peak seasons.

Keep some open space for future growth. Adapt floor layout without major renovation. Flexible options prevent overcrowding. Regularly review storage efficiency. Flexibility reduces long-term costs.

Integrating Automation

Automation can speed up pallet handling. Conveyor systems move pallets quickly between areas. Automated retrieval systems reduce labor needs. Use sensors to track inventory automatically. Ensure systems are safe and reliable.

Train staff to operate automation properly. Whether it’s a San Diego warehouse storage pallet storage or another facility, automation can improve workflow and reduce errors. Combine manual and automated processes where needed. Automation improves accuracy and saves time.

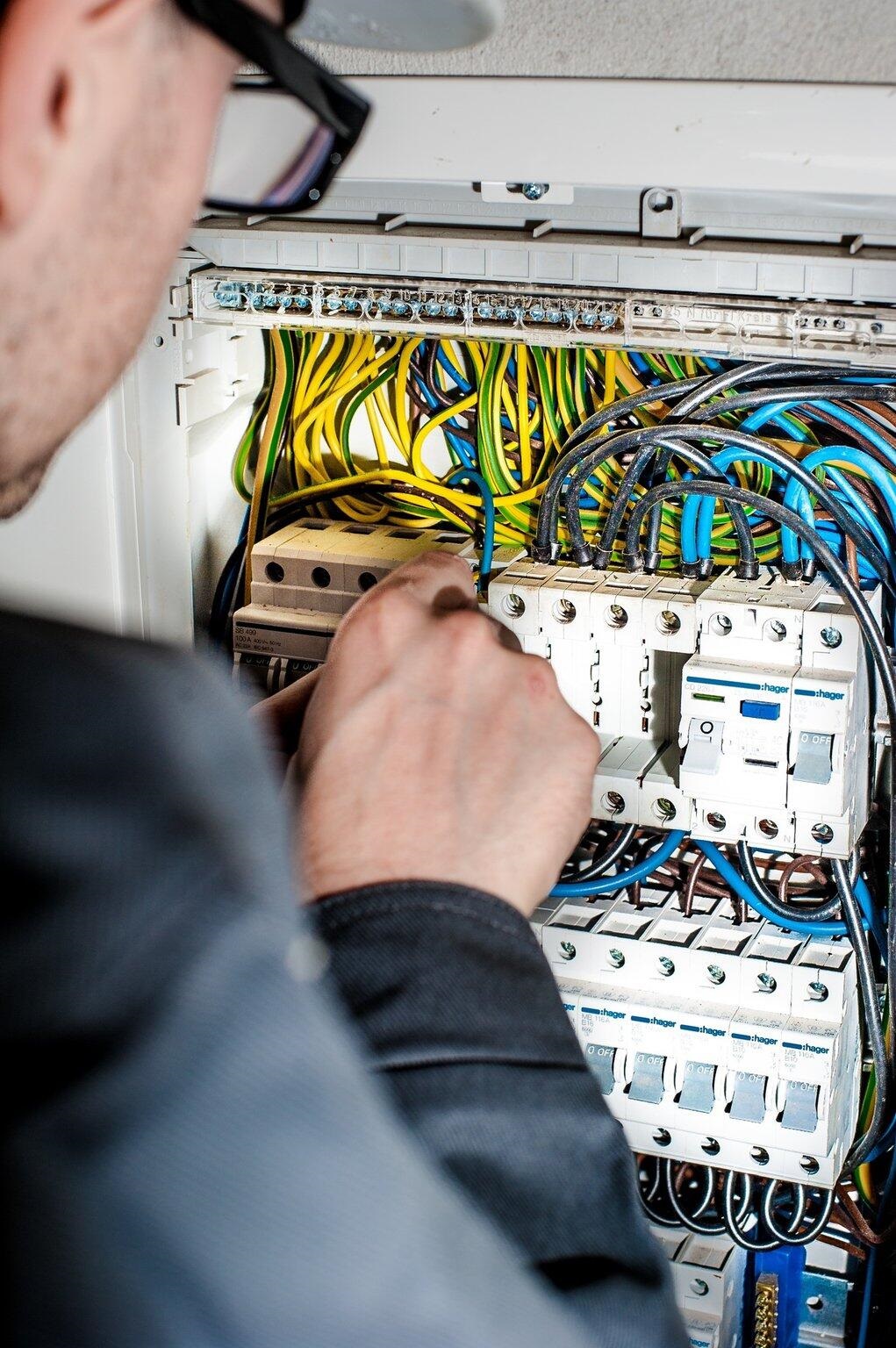

Regular Maintenance of Storage Equipment

Check racks and pallets often for damage. Replace broken or weak pallets quickly. Tighten loose bolts on shelving. Inspect forklifts and other handling equipment. Clean storage areas regularly to avoid clutter.

Make sure aisles stay clear of obstacles. Monitor moving parts on mobile racks. Schedule routine maintenance to prevent accidents. Regular care keeps storage safe and reliable.

Training Staff on Storage Procedures

Teach workers how to stack pallets safely. Show them proper use of forklifts. Explain labeling and tracking systems. Train staff on emergency protocols. Practice correct lifting techniques.

Encourage reporting of damaged equipment. Provide refresher courses regularly. Clear instructions reduce mistakes and accidents. Skilled staff improves warehouse efficiency.

Using Space-Saving Accessories

Add pallet supports or dividers for organized stacking. Use corner guards to prevent damage. Consider shelf liners for fragile items. Hooks and small racks help store accessories. Stack pallets in a uniform way.

Keep pathways clear for forklifts. Use adjustable shelving to fit different items. Organize by size or weight for efficiency. Accessories help maximize every inch of space.

Discover Warehouse Pallet Storage Solutions for Space Efficiency

Warehouse pallet storage solutions improve space use and workflow. Choosing the right racks, layout, and systems makes operations efficient. Safety and proper pallet selection prevent accidents.

Easy access and climate control protect inventory. Flexible and automated options save time and costs. Implementing these strategies leads to better organization. Start planning now to maximize warehouse efficiency.

To read more, visit our blog page. We do have more!